How Ti Build A Cage For Big Animals

There are many options for this type of cat enclosure. The easiest solution can exist to clad an existing pergola or patio with cat proof mesh, or fit a roof over a small-enclosed area such as a path between the business firm and fence.

There are many options for this type of cat enclosure. The easiest solution can exist to clad an existing pergola or patio with cat proof mesh, or fit a roof over a small-enclosed area such as a path between the business firm and fence.

If yous do not accept a suitable area then nosotros have instructions on how to build a patio style enclosure from the ground up. There are as well instructions for how to build a lightweight inexpensive culling that tin be constructed from galvanised water pipe and netting.

Read through the guide, examine your options, and so go ahead and design your project to suit your needs.

Things to consider when building a true cat enclosure

- Cats must take shelter from sun, wind and rain (even so they however require admission to sunshine in the enclosure).

- Cats must have a weatherproof sleeping compartment with a raised bed (which must be kept in a make clean and hygienic condition), along with a separate exercise expanse.

- The litter tray area must be well abroad from the true cat's eating and sleeping areas and must be kept dry and be easily cleaned. Litter trays must contain an advisable litter material and exist cleaned daily (many cats will not employ soiled litter, and volition therefore soil elsewhere in the enclosure).

- Accommodation should provide good ventilation, as this is vital to preclude build upwards of odours that can crusade respiratory problems in cats.

- Hygiene and odour shouldn't be a trouble as long equally your cat uses its litter tray and the tray is cleaned regularly. Notwithstanding, in the event of your true cat soiling the ground in the enclosure, you lot may have to consider adding some type of flooring. This could exist as simple as installing small gauge wire mesh on the floor to prevent cats from digging and soiling in the dirt. Alternatively, you could install concrete or timber flooring that will likewise be like shooting fish in a barrel to hose downwardly.

- Cats require plenty of social contact with owners. This can be achieved by providing access to the house through a cat door (and tunnel if applicable).

- Each enclosure should have a scratching pole and be designed to provide cats with at least two platforms at different heights. The platforms should be connected by static planks or swinging walkways. Cats should also accept access to climbing frames and an interesting visual outlook.

- In a grouping enclosure, a number of hiding and escape areas should be provided to enable cats to avoid assailment from other cats.

- The size of your enclosure will depend on the number of cats y'all wish to firm, and how well they become on. The floor surface area of an enclosure must be at to the lowest degree 2mii for each cat, with a minimum summit of 2 metres, plus tunnels and auxiliary enclosures. These dimensions take into account cats having regular access to the house.

The first and most simple solution is to bridge an existing surface area, such as a section between the house and fence, a veranda, patio or courtyard, with a lightweight support system and encompass information technology with netting.

If you lot are covering a small bridge, say between a wall and a debate to make a roof frame, take the measurements to your hardware supplier who tin propose you on suitable materials and fixing components. Although this choice doesn't involve building a full patio type construction, we recommend y'all withal read through these instructions, and apply annihilation relevant to your project.

Instructions on edifice a true cat enclosure

In the following section, we show you how to build two types of enclosures:

- Patio-type structure

- An culling lightweight enclosure.

How to build a patio-type structure

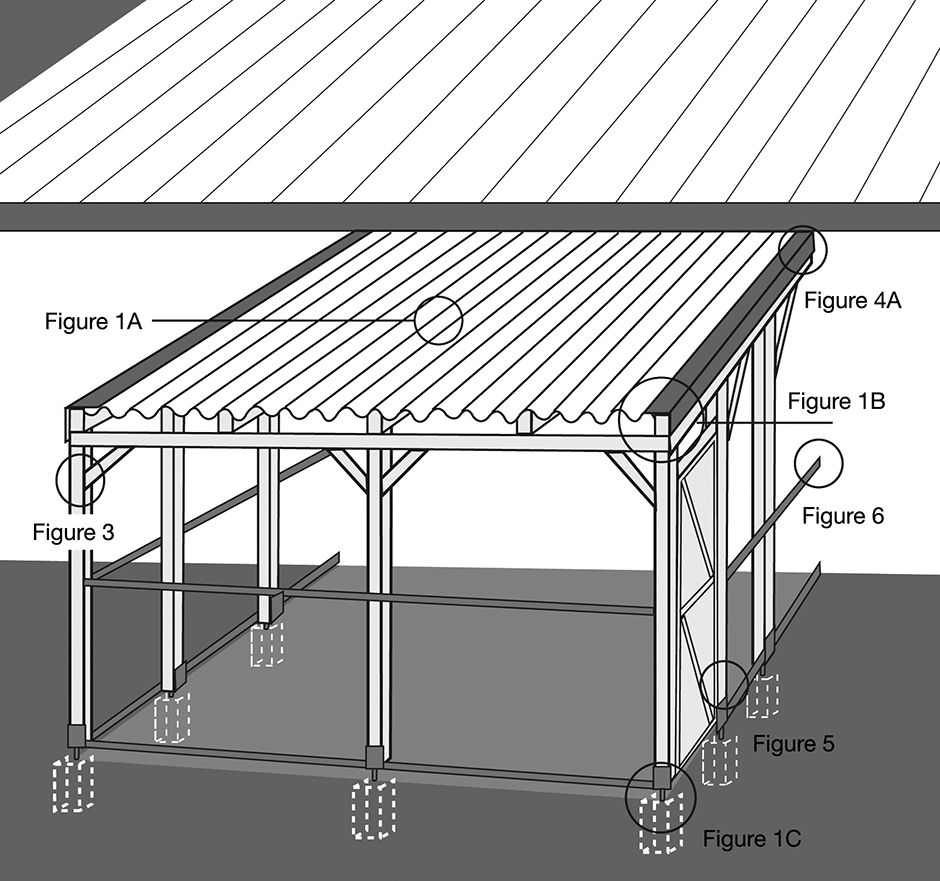

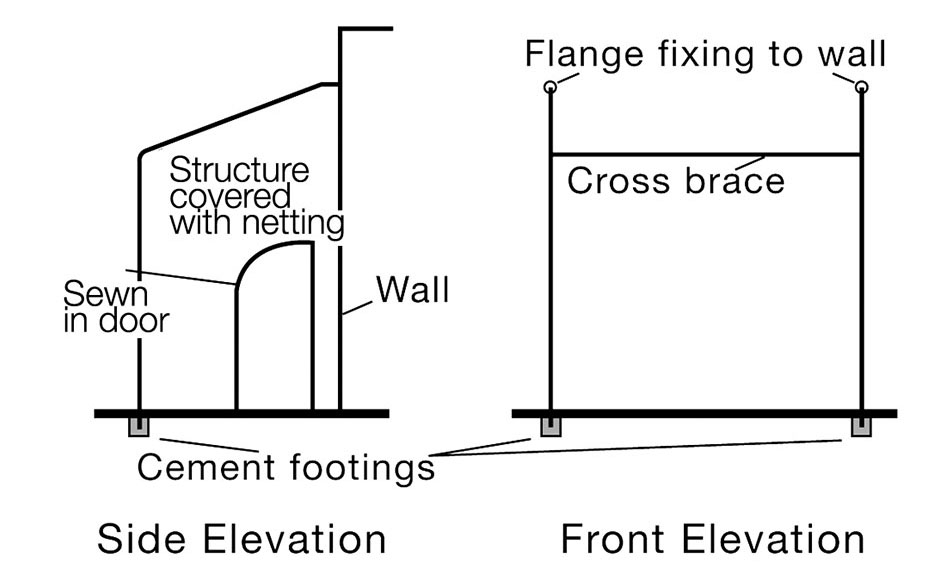

Patio blazon construction. This shows the basic building structure prior to the addition of solid weatherproof wall cladding on parts of the enclosure (to provide the cat with shelter) and prior to the add-on of other features (platforms, climbing planks, scratching posts, beds, etc)

To span a wide surface area, consider building a typical patio structure.

The near mutual patio type structure involves rafters fixed to the business firm or garage, and supported at the other end by posts. The posts are connected along the top by a timber plate, which supports the rafters. The best way to set the posts into the ground is to commodities them in a galvanised stirrup set in a concrete footing.

Battens are and so nailed across these rafters and the cladding fixed directly to the battens.

The bones construction is outlined in Figure 1.

Tools required

- drop saw

- handsaw

- spirit level

- drill

- string line

- shifting wrench

- hammer

- shovel

- center protection

- tape measure out

- hearing protection

- roofing square

- ladder

- Tec screw driver

- masonry or wood bits

Textile checklist

Firstly, draw upwards a working sketch of your projection and have information technology forth to your local hardware supplier who will advise on the appropriate timber dimensions and spacings required for your particular application. Include this data in your drawing and cheque with your local council to see if a building permit is required.

Exercise non use treated pino in the structure every bit information technology may prove toxic to cats, specially if used as a scratching mail. Typical timber dimensions and hardware requirements for an attached pergola approximately iv.8m × 3.6m.

Materials required

- 1 top plate, 200 × 50mm

- Framing brackets

- 3 posts 100 × 100mm

- 6 rafters 150 × 50mm

- two braces 75 × 50mm

- three post stirrups

- 2 rails 75 × 50mm

- concrete pre-mix

- 1 wall plate 150 × 38mm

- galvanised nails and bolts

- 3 joist hangers (fastened to the wall plate as per photograph)

- battens 45 × 22mm, (typically fitted at 450mm centres)

Structure

Footstep 1 — Set up out

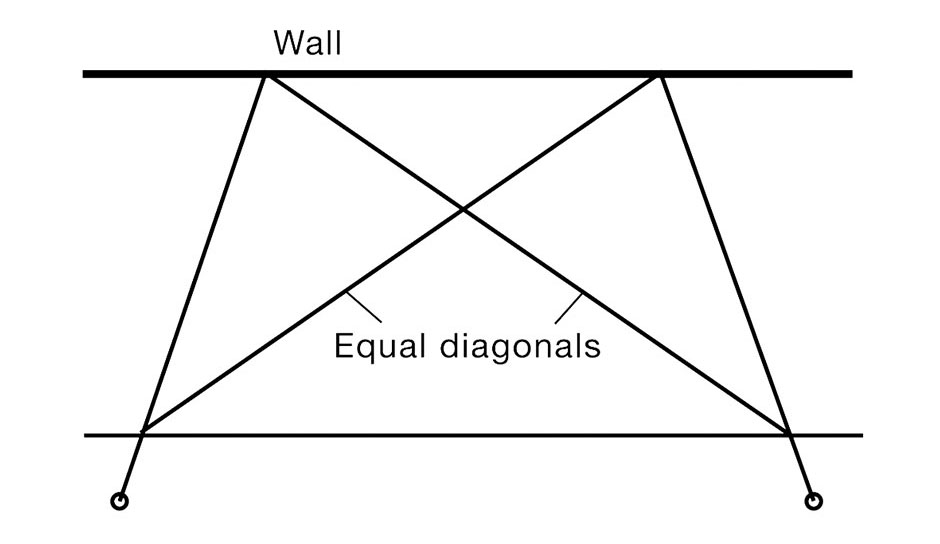

To set out the total size plan on the basis, place a string line parallel to the house along the exterior edge of the patio. Now set 2 string lines at correct angles to the house at each terminate of the enclosure. Check the set out is square past comparing corner-to-corner measurements, ensuring that they are equal. See Figure ii.

Permit spacing of iii metres or less between posts and mark their position forth the outer string line. Walk effectually your ready out to check dimensions and proportions.

Footstep ii — Setting the stirrup post supports

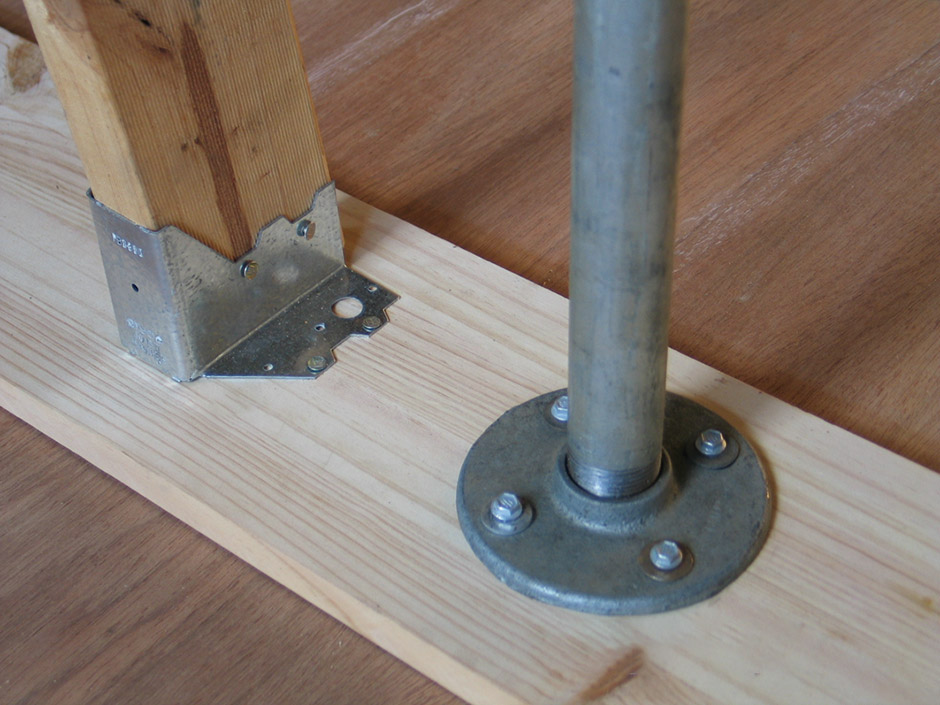

Dig 200 × 200mm holes to a depth of 300mm for each post. Come across Effigy 1C. Gear up the premixed physical and fill up the holes. Push the mail supports into the concrete ensuring that the stirrup is in a higher place the ground level. This will permit water to drain away from the bottom of the posts and preclude rot. Align each post support to the string line ensuring that they are all level and square.

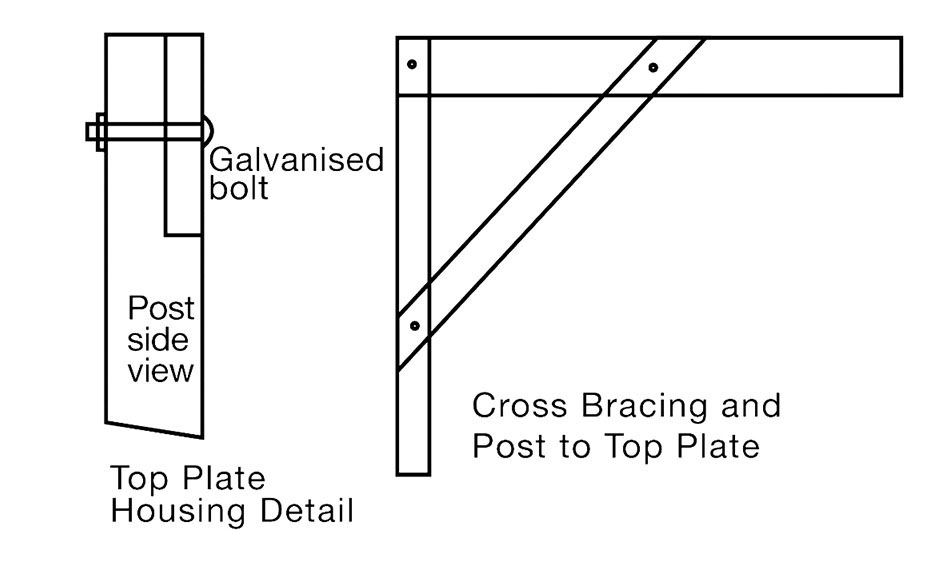

Get out the concrete to cure to specification. Drill and bolt the posts in position and secure each mail upright with temporary bracing. House (bank check in) and bolt the 200 × 50mm timber plate in position across the length of the posts and brace the stop posts to the summit plate with 150 × 50mm bracing bolted at 45 degrees. Run into Figure 3.

Please Annotation: If you are fixing the posts onto an existing slab, use postal service supports with a flat plate on the bottom. These are bolted in position with expanding masonry plugs. Your local hardware attendant tin show you this method.

Stride iii — Attaching a pergola to the house and fixing rafters

Stride iii — Attaching a pergola to the house and fixing rafters

Kickoff fit a wall plate to the house, this wall plate is stock-still to the wall of a brick house under the eaves with masonry plugs, or to a timber house with omnibus bolts screwed through the weatherboards and into the frame. The rafters are then stock-still to the wall plate with joist hangers, and span across to the pinnacle plate at approximately 600mm intervals or less and gear up with framing brackets or skew nails.

Step four — Fixing battens

Battens are evenly spaced across the rafters at approximately 900mm intervals or less and nailed in position with galvanised nails. Battens should exist predrilled to avoid the timber splitting.

Step 5 — Access door

The door is a simple brace and rail construction made from hardwood bolted together with galvanised bolts and clad with mesh. The door is hung between two vertical posts with a header bolted across at door peak. If there are any children effectually so consider a childproof latch on the external door. See Figure v.

Stride vi — Finishing the timber structure

Think that treated pine is not an option so you volition demand to seal the timber to protect it from weathering with a good quality outside terminate. Pigment the internal faces of the joints before assembly.

Step 7 — Roofing/weather condition proof cladding

Note that in some cases it may be a legal requirement that a licensed plumber is required to fit the roofing and flashing (contact your local water supplier for details).

Corrugated steel products

Zincalume and Colourbond sheeting can be used for roof and fractional wall cladding. If you live by the coast then specify corrosion resistant steel sheeting. These products are hands fixed, however the structure must be sound. They are weatherproof and permanent merely practice restrict natural light, which is a consideration when enclosing an external wall containing windows. In this situation, clear polycarbonate sheeting such as Laserlight and Suntuff is an platonic solution.

There are a wide range of grades available, which accept differing low-cal and estrus manual characteristics. Each product comes with specific fixing instructions, which must be followed. Remember that some part of the enclosure must provide cats with access to sunshine, while other areas must give shelter from the sun.

If y'all are probable to climb on polycarbonate roof cladding, yous may wish to install a condom barrier directly underneath the textile to prevent accidental falls. Ask your supplier to recommend a low-cal wire mesh that can be fixed on height of the battens. The sheeting and end flashing is then stock-still to the battens with cocky-tapping Tec screws and rubber washers.

You may want to consider installing guttering and a downpipe, if excess water run-off from the enclosure roof is a problem. The gutter should exist stock-still just below the line of the roofing, beyond the outside of the end beam. Remember to permit for a second fall, so rainwater tin run forth a slight slope in the gutter and menses into the downpipe.

The piping needs to exist attached to the nearest stormwater outlet. Seek advice from your local hardware store, or contact a qualified plumber for assistance installing a gutter and downpipe.

Step 8 — Wall cladding options

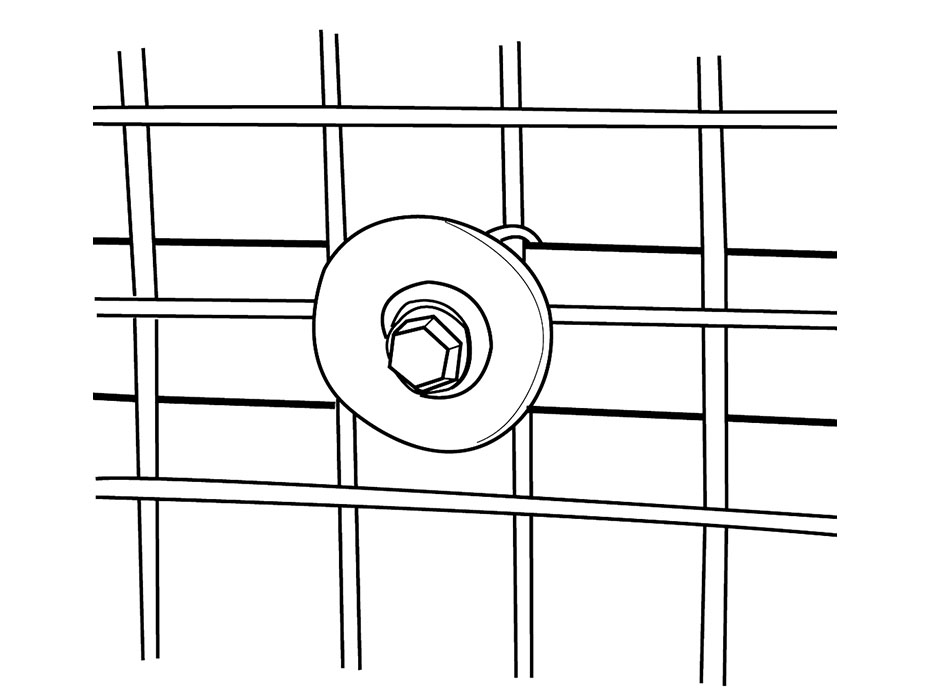

Galvanised welded mesh is rustproof and available in a wide range of sizes and gauges. The maximum mesh size recommended for cat enclosures is 50 × fifty mm. A well-fixed 4-gauge mesh will provide reasonable security for your enclosure and is strong enough to back up climbing plants if yous add them. Metal mesh is fixed to the timber posts and timber rails with staples or washers and Tec screws depending on mesh sizes and loading. See Figure 6.

Light flexible mesh is held in position with a timber batten nailed to posts or your existing structure (house or fence). Ask your mesh supplier to advise on the optimum fixing method for your awarding.

Lightweight 25 × 25 mm mesh makes a expert barrier where security is not a consideration. The mesh can exist fixed with washers and Tec screws.

Galvanised chicken wire is a cheap alternative and is fixed with battens anchored to the base structure.

Shade material is bachelor in a wide range of colours and opacities making it a adept option for your enclosure. Information technology has good UV stability and will last for years, however it should be checked occasionally for signs of weakness. It is stock-still to the structure with special fasteners that are available from your shade fabric supplier.

Shadecloth walls are prone to damage from climbing cats and tin exist strengthened with metallic mesh.

Insect screening can exist incorporated into the structure but it needs to exist supported by a stronger mesh.

Commercial netting products — any netting is suitable if it is:

- potent

- UV stable

- rot resistant

Access doors tin can be sewn in with a zip fastener. See supplier list, at the end of this guide.

Please Notation: If netting is to exist used to clad the enclosure and so a wooden board needs to be set into the basis around the perimeter of the enclosure.

How to build an culling lightweight enclosure

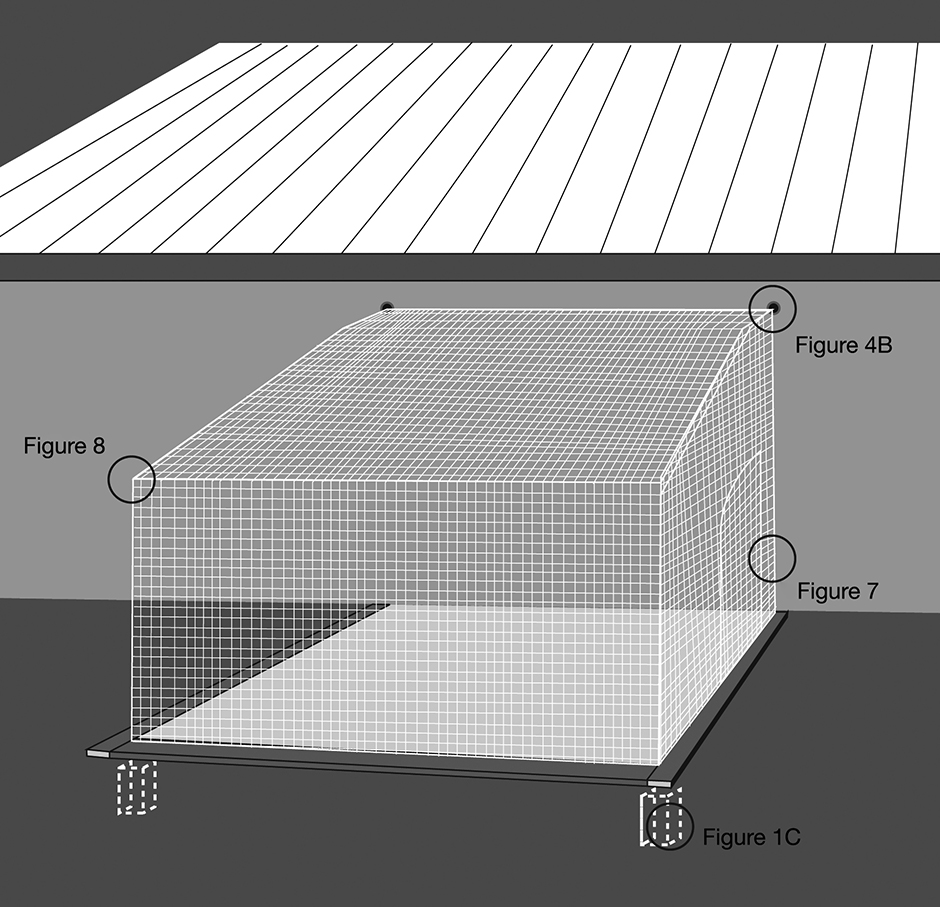

This enclosure is a lightweight alternative to the patio structure and is intended to exist covered with flexible netting that has a sewn in door.

The structure will not support a roof and is unsuitable for other mesh cladding. This type of lightweight enclosure is merely suitable if the cat has constant admission to the owner's house through a cat door, and then it can seek shelter during inclement weather.

The frame is fabricated from round galvanised steel tubing that is bent at an angle, fixed to the wall at the top, and ready in physical pads in the basis at the other end. See Effigy 7.

To provide lateral support, the structure will need to be cantankerous-braced or fixed to something solid, for instance a debate.

The recommended wall fitting is a metal flange that is threaded onto the pipe and stock-still to the structure by ways of bus bolts or masonry plugs.

The other end of the piping is set into a concrete footing. Bracing is attached with prefab pipefittings that are readily available from your supplier.

The structure can be covered with a prefabricated flexible netting cover with a sewn in zippered archway.

Tools required

- shovel

- spirit level

- drill

- roofing square

- masonry or wood bits

- shifting spanner

Materials required

- galvanised pipe

- prefab pipe fitting

- screw on flanges

- flexible netting encompass

- coach bolts or masonry plugs

- tie wire

- physical pre-mix

Step 1 — Basic blueprint and pre-fabrication

Draw the basic plan and discuss it with your steel supplier who can recommend the best pipage bore, usually effectually 50mm. Have the pipe cut to length and aptitude.

Based on your design identify pipes that need to be threaded on the height cease to suit the screw-on flanges for fixing and have them threaded at the time of buy.

Most suppliers have a delivery service for hard to handle components.

Stride 2 — Set out

Showtime construction with a string line parallel to the supporting wall at the exterior perimeter and another ii cord lines at correct angles to the wall marking each end. Meet Figure 2.

Step iii — Setting the frame posts

- Dig the footings and cock the structure ensuring that it is well braced. Take a spirit level and sight all pipes from all angles to make sure they are in alignment with each other and in alignment with the back up construction. Accept intendance with this stage, as a poorly aligned frame can look shoddy.

- Fit the bracing to square the frame and level the pinnacle bars by packing the lesser of the pipes with modest rocks in the footing holes.

- When you are happy that everything is directly and square, mix up a quantity of premix cement and pour the footings. Allow to set to specification.

- Set a wooden board into the basis all around the perimeter. The prefabricated netting cover will be fastened to this board.

- Mensurate the finished project for the prefabricated netting.

Step iv — Fixing the netting

The netting is tied to the frame with galvanised tie wire. It is fixed to wood and masonry with battens, the same as for patio construction.

Source: https://agriculture.vic.gov.au/livestock-and-animals/animal-welfare-victoria/cats/enclosures-and-fencing/building-a-cat-enclosure-attached-to-an-existing-structure

Posted by: johnsonyoustion.blogspot.com

0 Response to "How Ti Build A Cage For Big Animals"

Post a Comment